Services

Keep your costs down with a manufacturing partner.

Reduce customer costs by consolidating materials and higher volume operations with MFG Spare. Running your own machine shop can be expensive and time-consuming, but we’re here to help. We provide the same quality parts as international providers at a lower cost and in a shorter time—without the hassles of running your own machine shop.

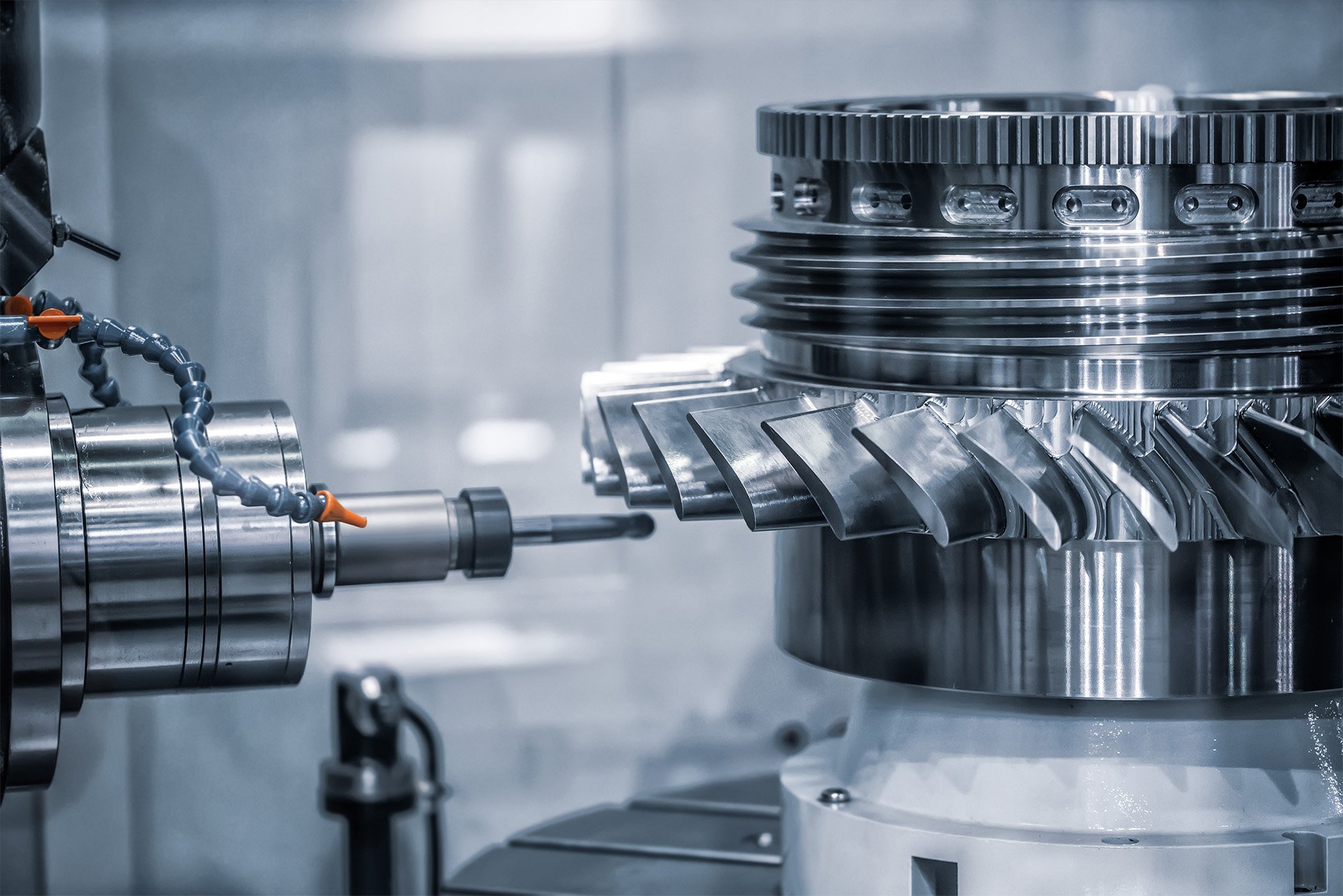

CNC Machining

CNC machining is a manufacturing technique that utilizes computerized controls and machine tools to take away layers of material from a component which is commonly referred to as the blank or workpiece and produces a custom-made piece. This method is suitable for a variety of materials.

Finishing

- As machined, Fine machining, polished,

- brushed and Bead Blasting

- Anodizing Type II (clear or color) and anodizing Type III (hardcoat)

- Powder coating, Nickel Plating and black oxide

Materials available to start work immediately in CNC Machine

- Aluminum (6061-T6, 7075-T6, 6082, 5083, 6063, 5052, 2024, 7050, MIC6, 2017, A380 and 2014)

- Stainless Steel (304, 316, 303, 17-4PH, 416, 2205 Duplex, 420, 440C, 430, 301, and 15-5),

- Mild Steel (1018, C45, S355J2, 1045, S235JR, A36, S275)Brass (Cz121/C360, C360)

- Copper (C110, C101)

- Alloy Steel (1.7131, 4140, 1.7131, 4340, 1215)

- Tool Steel (D2, A2, O1, A3, S7, H13)

- Titanium (Grade 5, Grade 2, Grade 1)

- Inconel (718)

- Invar

Plastics

- POM [Delrin/Acetal] (POM-H, POM-C)

- Nylon (6, 6 30% Glass Filled)

- ABS

- PEEK

- PTFE [Teflon]

- Polycarbonate

- Polyethylene (HDPE, UHMW-PE)

- PVC

- PMMA (Acrylic)

- PET

- Polypropylene (PP, PP+GF 30%)

- G-10

- FR4

Sheet Metal

A laser-operated machine cutter can be used to create weldable and flexible prototypes through the process of stretching, bending, and material removal.

Materials available to immediately start work on Sheet metal

- Aluminum 5052

- Aluminum 5754

- Copper C110

- Stainless steel 304

- Stainless steel 316

- Steel 1018

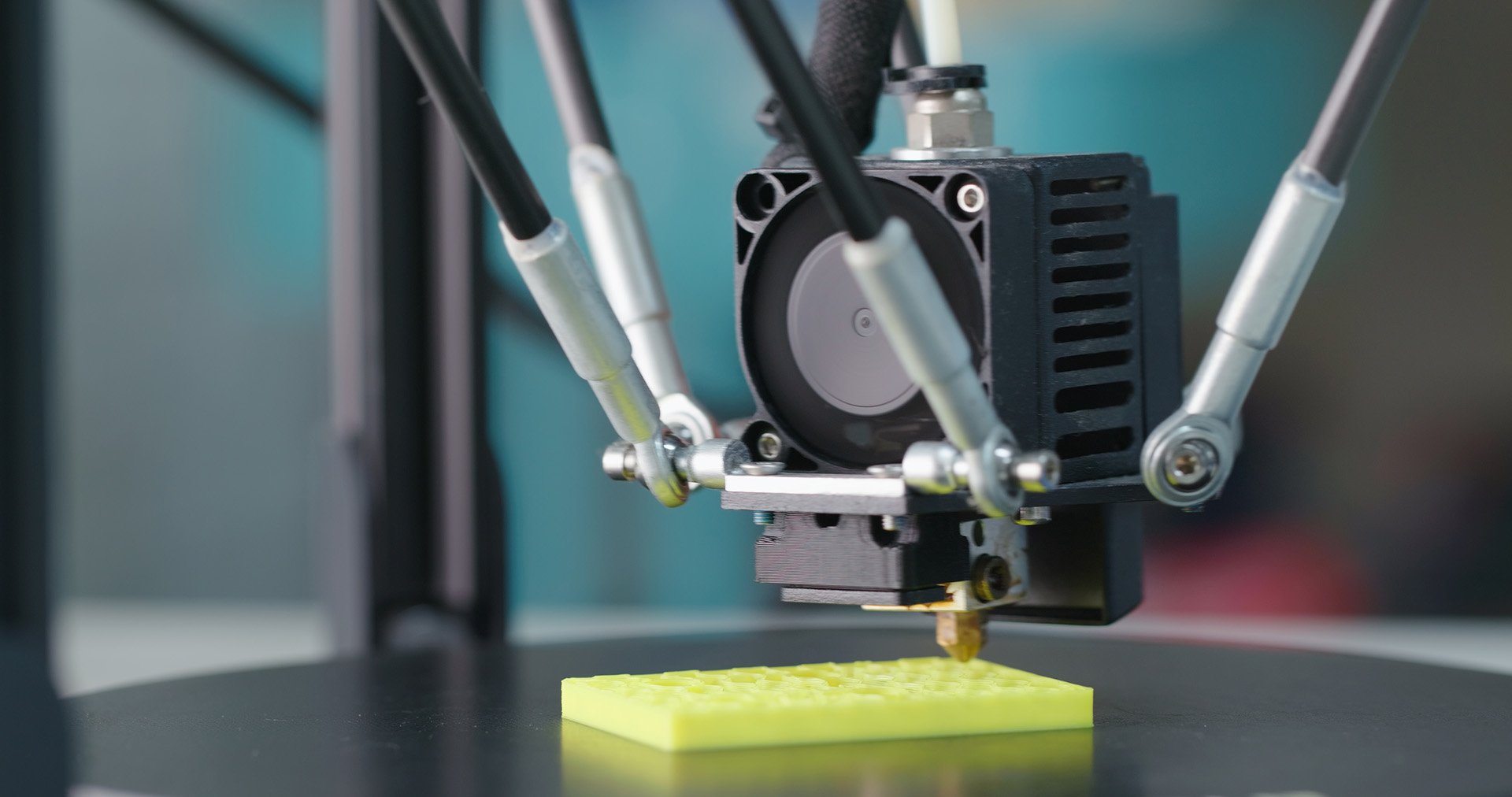

3D Printing

By utilizing computer-aided design, 3D printing can manufacture three-dimensional objects through a step-by-step layering process. Also known as additive manufacturing, this technology layers materials such as plastic, composites, and bio-materials to create objects with varying shapes, sizes, strength, and colors.

Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF)

Materials available to start work immediately in 3D Printing

- PLA

- ABS (ABSplus, ABS-M30)

- Nylon (PA 12, PA 12 Glass Filled)

- Resin (Standard, Clear, Tough 2000, Rigid 4000, Grey Pro, Flexible 80A, High Temp, Durable)

- PETG

- TPU

- ASA

- PEI (ULTEM 9085, ULTEM 1010)

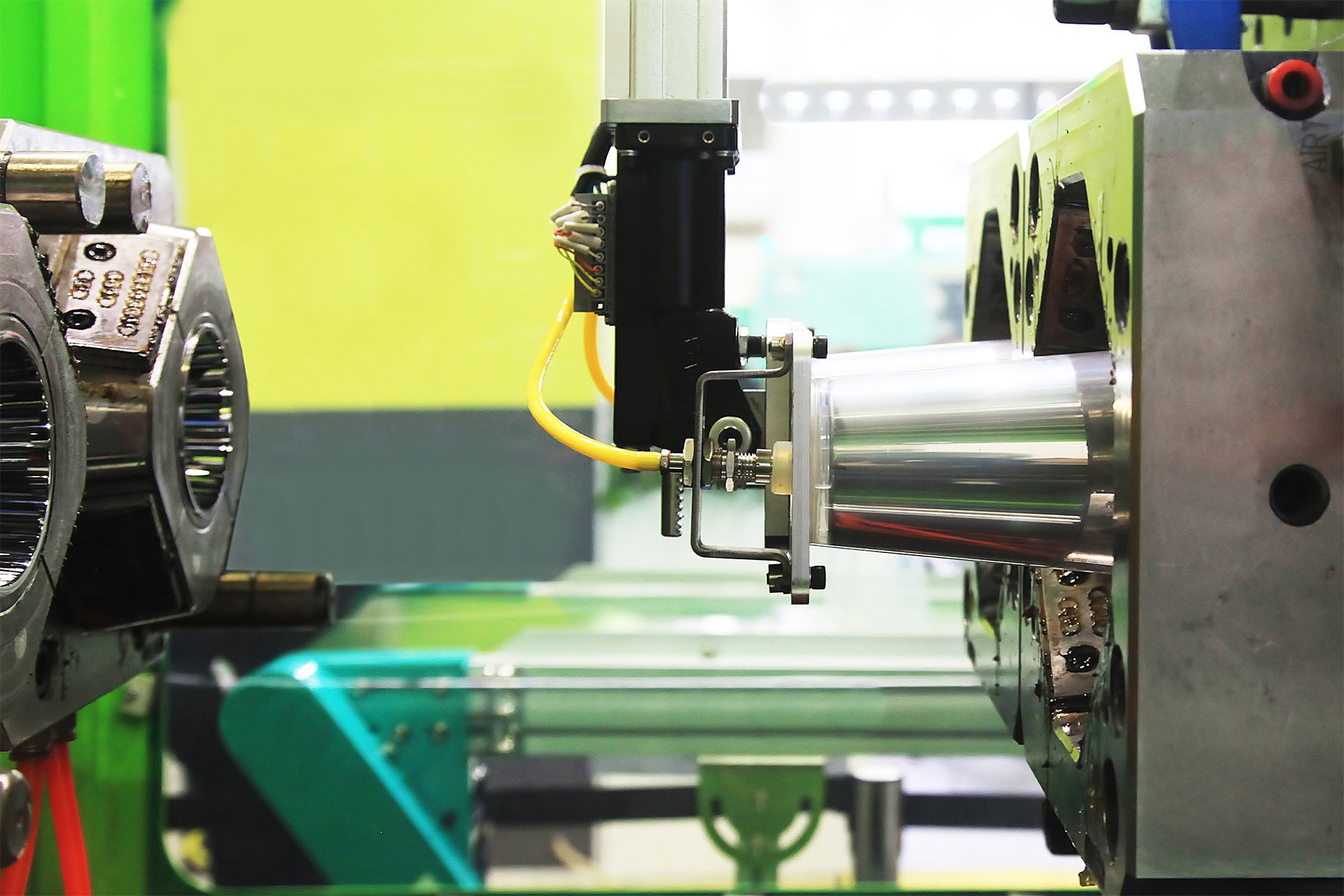

Injection Molding

The injection moulding technique involves forcing molten materials into a set shape. This is commonly used for the production of huge batches of identical items. Metals, glass, rubbers and some food items can be injected, but most of the materials used are thermoplastic and thermosetting polymers.